- Mezzanine Floors

- Solutions

- Multi-Tier Mezzanines

- Mezzanine Pallet Safety Gates

- Mezzanine Staircases

- Mezzanine Handrails and Balustrades

- Mezzanine Decking

- Fire Protection for Mezzanine Floors

- Mezzanine Lift Shaft Design and Installation

- Resources

- Mezzanine Floor Calculator

- Mezzanine Floor Regulations and Building Control

- Self-Storage Mezzanine Floors

- Self-Storage Units

- Resources

- Self-Storage Site Selection Information

- Calculating The ROI of Self-Storage Conversions

- Planning for Automation in Self Storage

- Racking & Shelving

- Solutions

- Cantilever Racking

- Pallet Racking

- Coil Racking

- Longspan Shelving

- Tyre Racking

- Kimer Racking

- Live Storage Racking

- Drive In & Drive Through Racking

- Clip Shelving

- Mobile Shelving

- Custom Fabrications

- About Us

- USS Case Studies

- Self-Storage Fit-out For Raked Ceiling Building

- Mezzanine And Staircases For Entertainment Venue

- New Mezzanine And Staircases For Major Retailer

- Mezzanine Pallet Safety Gate

- Self-Storage Fit-Out Project For Brand New Facility

- Warehouse Racking, Wire Mesh & Shelving for New Warehouse

- Self-Storage Partition System & Components Installation

- Self-Storage Store Mezzanine And Staircases

- Multi-Tier Mezzanine For Logistics & Distribution Facility

- Warehouse Plant Platform

- Self-Storage Facility Space Expansion

- Mezzanine Floor For Distribution Warehouse

- Bespoke Feature Staircase & Mezzanine

- Single Level, Multi-Use Mezzanine

- Mezzanine For A New Building

- Mezzanine Floor For Plumbing Supplies Warehouse

- New Racking System and Mezzanine Floor

- Car Park Conversion To Self Storage Facility

- Pallet Racking and Cantilever Racking For Warehouse

- Two Mezzanine Floors For Self-Storage Facility In Birmingham

- Our Accreditations

- Contact Us

- USS Case Studies

- Frame – the upright section of the racking, consisting of two vertical supports connected using diagonal and horizontal braces.

- Beam – the beams are the horizontal, load-bearing structures joining the two frames together. Once two beams have been attached to the frames, a 'beam level' is created, and it is on the beam level that products or pallets are placed.

- Bay – two frames and the beams joining them together constitute a single bay.

- Run – a run is a continuous row of bays joined together.

- Anti-collapse mesh

- Column guards

- Pallet support bars

- Fork spacers

- Drum cradles

- Hanging garment rails

- Guide rails

- Location and load signage

- End barriers

- Corner guards

- Dividers

The Latest Blogs From USS

Warehouse Racking and Storage - Your Questions Answered

read

We work with companies all over the UK, helping them to maximise their warehouse storage options - and making sure no potential space-utilisation opportunity gets overlooked!

Over the course of our years in the business, different clients ask many similar questions - for which we are always delighted to answer and give advice. However, most questions arise from the same fundamental challenges - or a need to understand what benefits different types of racking and storage solutions offer. So, we spoke to the USS team and asked them to come up with the questions they get asked the most - and more importantly, to give us their answers.

Here's the result. A USS hit list of questions you are most likely to want to be answered when you're looking for the best racking solution for your warehouse.

What is Pallet Racking?

Pallet racking comprises shelves supported by frames that form horizontal rows to store items. The terminology used to describe a pallet racking system includes the following terms:

The majority of pallet racking is loaded and unloaded using forklift trucks or similar specialised lifting equipment. We can provide custom solutions with the shelving positioned to accommodate a range of stock and load sizes. Opting for modular pallet racking means you have the option to modify the racking as your business requirements change.

What Are The Different Types of Pallet Racking?

Pallet racking is diverse; it comes in various heights, widths and depths, with weight loading capacity designed and built into the system as required. The most common type of pallet racking is selective pallet racking, which is ideal for a warehouse utilising the first-in, first-out method of loading and unloading. If your warehouse uses reach trucks to load and unload the pallet racking, the minimum floor space between aisles must be 3.5m or 4.5m for counterbalanced forklifts. Selective pallet racking of this kind is one pallet deep, meaning that storage density is lower, but on the upside, individual items are easy to reach.

Today, there are a wide range of specialised racking solutions available for just about every need:

Galvanised Racking

This racking is a heavy-duty solution that is perfect for use when storing items outside. The galvanised steel is high strength and resistant to corrosion, meaning it can cope with problems such as bad weather.

Wide Aisle Racking

This type of racking is suitable for use with counterbalance or reach forklift trucks, making it the ideal solution for stock that has to be easily accessed and rotated.

Narrow Aisle Racking

This type of racking utilises specialist forklift trucks featuring wire guidance; it makes maximum use of the available space.

High Bay Racking

High bay racking is another form of racking for use with specialised forklift trucks or stacker cranes. It's a system that makes excellent use of the space available in a warehouse.

Double-Reach Racking

Double reach racking is two rows deep. By placing double-reach racking back to back, it is possible to significantly reduce the number of aisles in a warehouse, maximising the space given over to actual storage. When placed against a wall, this type of racking will require a specialised forklift truck to access all the available stock. However, if space allows, the same racking could be accessed from the other side using a standard forklift truck.

Long Span Racking

Long span racking is a cheaper but less robust alternative to standard pallet racking. Usually, it can only handle loads of 500kg UDL per pair and is not suited for use with forklift trucks due to the damage any impact could cause. Our long span racking frames are available from stock in heights of 2.0, 2.5, 3.0 and 4.0 metres and depths of 600 and 900 mm. Beams are available from stock in the following sizes - 1500mm, 1850mm, 2250mm and 2700mm.

Cantilever Racking

Cantilever racking can support loads that are wider than the actual span of the racking, making it the ideal choice for items such as long pipes and rolls of carpet. It can be installed as a single or double-sided solution and usually supports 1000kg per arm UDL. We can design the arm length, height and maximum loading to meet customer requirements.

Coil Racking and Cable Racking

These two types of racking are highly specialised in nature. Cable racking is the storage solution for heavy drums which store cable. The loaded racking permits the cable to either unroll from a drum and cut to length or unload fully.

Coil racking offers a similar solution but for coils of material small enough to be loaded by hand. In both cases, we can provide galvanised coil and cable racking for use outdoors.

Drive-In or Drive-Through Racking

This system allows the storage of pallets on rails, with the drive-in option being suited to "first in last out" stock rotation and the drive-through option for "first in first out" stock rotation. Both cases optimise space - although drive-through racking offers most benefits in terms of accessibility.

Push-Back Racking

Push-back racking features pallets placed on mobile carts that slide back and nest as each new pallet is added. If the products stored are of consistent weight and size, then push-back racking is an ideal solution for warehouses where space is at a premium.

Tyre Racking

Using customisable long span racking creates tyre racking. Manufactured in steel, it offers a powder coat finish and handles specific tyre dimensions and widths. As is the case with many of the racking systems supplied by USS, tyre racking can be custom finished to meet the broader branding of a company.

Which Sizes of Racking Can USS Provide From Stock?

We can provide frames from stock which are 3.0, 4.0, 5.0 and 6.0 metres in height and depths of 600, 900 and 1100 mm. Beams from stock are available in sizes of 1.35 and 2.7 metres and can cope with a safe working load of up to 3000kgs UDL per pair. We can also provide frame sizes up to 12.0 metres, and beam sizes up to 3.9 metres.

What is Pallet Racking Best For?

Pallet racking provides the ideal storage solution for items in boxes, crates or other containers, but bear in mind; it is unsuitable for unpackaged bulk materials. With careful planning and design, pallet racking can significantly reduce the working hours involved in processing orders and locating and handling stock in a manner that is quick and efficient while still being completely safe.

What Accessories Can Enhance a Racking System's Utility?

Although a standard racking system may well get the job done in terms of storage, it is possible to add several different accessories to create a truly bespoke storage system and protect the operation and integrity of that system. Examples are as follows:

Can Pallet Racking Configuration Be Changed After Installation?

Pallet racking systems can be altered after installation, particularly if you opt for a modular solution. The overriding concern should always centre on the safety of the racking, so make sure that any alterations made don't go beyond the system's tolerances. For this reason, when making alterations such as moving the load-bearing parts of the system or adding/moving aisles, it is always best to consult with the original installers of the system.

How Should I Plan Warehouse Racking?

The key to warehouse planning includes considering the type, size and layout and knowing precisely how and when items move in and out of the warehouse. The aim is to create a design that maximises the utilised floor space whilst streamlining product movement through the warehouse. When creating the initial floor plan, pay close attention to factors such as where office space is needed and where goods will be received, sorted, packed and shipped. We've written some great advice on planning warehouse racking if you want more information about this vital aspect of a racking project.

How is Warehouse Racking Installed?

The first stage of installation involves analysing the space available, looking at aspects such as durability and stability of the floor and the presence of any plant and/or equipment. Once analysis is complete and the installation team has established the safest and most efficient means of installing the racking, it will be installed and secured in line with regulations set out by the storage equipment manufacturers association (SEMA). Firstly the frames are constructed using vertical supports, braces and base plates, and then the constructed frame is secured to the floor. The next stage is for the racking beams to be slotted into place and fastened using a method chosen for the specific type of racking and the load-bearing needed. The final stage is decking installation, usually constructed from a material such as steel, wire mesh or chipboard.

How Much Weight Can Warehouse Racking Hold?

The amount of load a particular racking system will bear depends on several factors, such as the size and type of the racking itself and the capacity and condition of the floor slab where the installed racking will sit. The maximum load will also depend upon whether the frame is standard, medium or heavy-duty. In some cases, it's possible to modify an existing racking system to cope with heavier loads using reinforcements. Calculating how much expected weight the racking is to bear is an essential aspect of any racking installation plan. It should take into consideration what you need now and in the future.

What is The Maximum Height For Warehouse Racking?

As with the maximum load-bearing capacity of warehouse racking, the maximum size of any racking system depends upon a range of factors. Not least of these is the height of the facility itself, the type of racking system used and the load capacity of fully stocked racks. Another factor to bear in mind is the reach of any handling equipment used to place and remove stock on the racking. Most standard forklifts can reach heights of 4 to 4.5 metres, so racking, which is higher than this, will be challenging to access. The Health and Safety Executive have published extensive guidance on the safety of stacking heights. Ultimately, what drives the final choice is a combination of safety, efficiency, the type of stock to be stored and the space available.

Can Warehouse Racking be Used With Mezzanine Flooring?

The simple answer to this question is yes, and we have both experience and expertise in the design and installation of mezzanine flooring solutions for warehouses and distribution centres. Installing a mezzanine floor within a space such as a warehouse will instantly increase the available floor space without physically expanding the building itself. It does this by taking advantage of additional vertical space which would otherwise go to waste. Once in place, the mezzanine floor could support further racking or facilities such as office and reception areas. Shifting aspects such as this up onto the mezzanine floor will free up space on the ground floor to allow for existing racking to be extended. The majority of mezzanine floors installed in existing buildings don't require planning permission, as they are demountable and not attached to the actual fabric of the building.

How Can I Protect My Warehouse Racking From Damage?

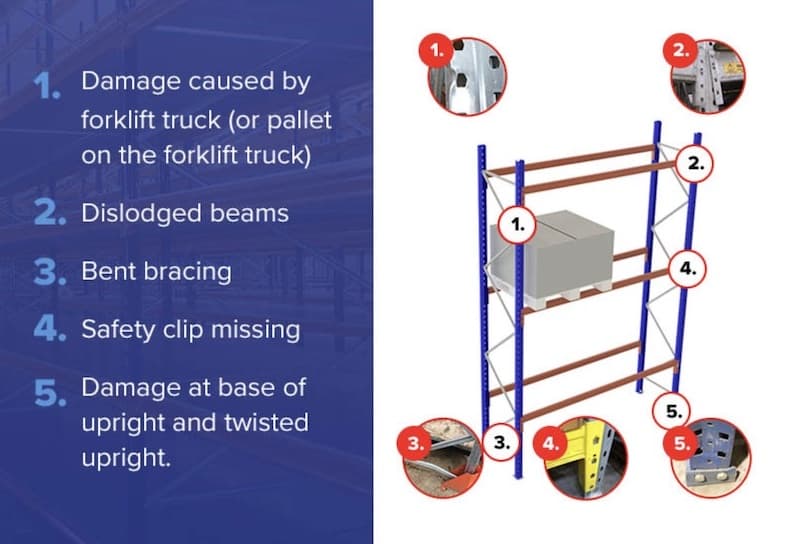

The practical reality of the working life of most racking systems means that they are vulnerable to damage from a range of sources. Racking, utilised outdoors, might be subject to corrosion caused by exposure to the elements, while racking in a warehouse is often knocked and bumped by handling equipment such as forklift trucks. This post has some great advice on the prevention and causes of warehouse racking damage.

Prevent damage such as corrosion by the regular application of chemical protection treatments. In contrast, achieve physical protection by strategically placing items such as guard rails and shock absorbent barriers. In general terms, the best way to protect any warehouse racking system is to ensure regular inspection and maintenance.

Does Warehouse Racking Need to be Inspected?

Yes, racking inspections should occur regularly. It would be best if you also carried out additional checks on each rack's structural integrity after any collisions with handling equipment such as forklift trucks. Health and Safety legislation states that yearly expert inspections are required, but it would be wise to have heavy traffic areas tested more regularly. The team at USS can carry out checks triggered by suspected damage following a collision with handling equipment or on a schedule. Our inspectors are SEMA-approved Racking Inspectors recognised by the HSE. Following a full inspection, they will submit a written report detailing whether any aspects of the system need to be repaired, maintained or replaced.

This blog is for information purposes only and should not be construed as legal or financial advice and not intended to be substituted as legal or financial advice.

Find Us

S & L United Storage Systems Ltd

United House, The Street

Takeley, Bishop's Stortford

Hertfordshire, CM22 6QR

Company No. 1313816

VAT No. 291616253Say Hello

01279 871 787Copyright © 2025 S & L United Storage Systems Ltd. All rights reserved.

- About Us